Medical professionals and caregivers rely on Bard Dispoz-a-Bag systems for effective urological drainage management. However, even the most reliable medical equipment requires maintenance over time. The cap component of your Bard Dispoz-a-Bag system plays a crucial role in maintaining sterility and preventing leakage, making proper Bard Dispoz-a-Bag cap replacement an essential skill for healthcare providers.

Understanding when and how to replace these caps ensures optimal patient care while maintaining the integrity of the drainage system. This comprehensive guide walks you through every aspect of cap replacement, from identifying when replacement is necessary to proper installation techniques that maintain sterility standards.

Whether you’re dealing with routine maintenance or unexpected cap failure, having the right knowledge prevents complications and ensures continuous, reliable function of your Bard Dispoz-a-Bag system.

Understanding Bard Dispoz-a-Bag Caps and Their Function

Bard Dispoz-a-Bag caps serve multiple critical functions within urological drainage systems. These specialized components create an airtight seal that prevents contamination while allowing controlled access for drainage procedures. The cap design incorporates safety features that minimize the risk of accidental disconnection during patient care.

Medical-grade materials used in these caps resist degradation from constant exposure to bodily fluids and cleaning solutions. However, repeated use, environmental factors, and normal wear patterns eventually compromise their effectiveness. Regular inspection helps identify when replacement becomes necessary before system failure occurs.

The engineering behind these caps balances ease of use with security features. Healthcare providers can quickly access the system when needed while maintaining sterile conditions throughout the process. Understanding these design principles helps medical professionals make informed decisions about replacement timing and proper handling procedures.

Common Issues Requiring Bard Dispoz-a-Bag Cap Replacement

Several factors contribute to cap deterioration and the need for replacement. Physical wear represents the most common cause, as repeated opening and closing gradually degrades the sealing mechanism. Healthcare environments subject caps to frequent handling, increasing the likelihood of mechanical stress that compromises integrity.

Chemical exposure from cleaning agents and bodily fluids can cause material degradation over time. Certain medications and solutions may accelerate this process, particularly in patients receiving specific treatments that alter the chemical composition of drainage fluids. Regular monitoring helps identify early signs of chemical damage before complete failure occurs.

Temperature fluctuations in healthcare settings sometimes affect cap materials, causing expansion and contraction cycles that weaken sealing surfaces. Storage conditions also impact longevity, with extreme temperatures or humidity levels potentially compromising performance. Proper storage protocols extend cap life and reduce replacement frequency.

Accidental damage during handling or transport creates another common replacement scenario. Dropped equipment, excessive force during procedures, or contact with sharp objects can crack or deform caps. Immediate replacement prevents contamination risks and ensures continued system reliability.

Identifying the Correct Replacement Cap

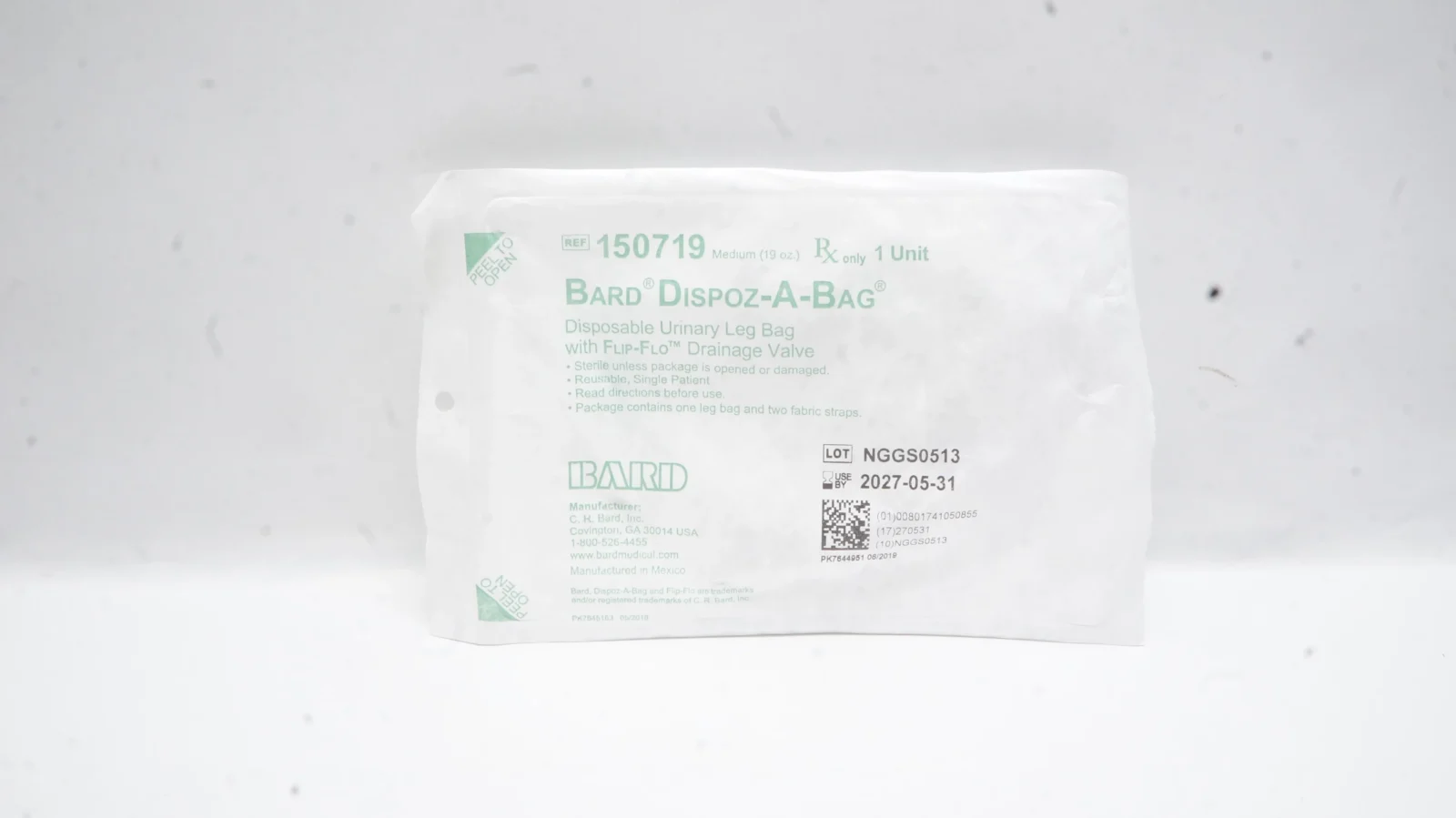

Proper identification ensures compatibility and maintains system integrity. Bard produces multiple cap variants designed for specific Dispoz-a-Bag models, making accurate identification crucial for successful replacement. Model numbers printed on existing caps provide the most reliable identification method.

Package labeling includes detailed specifications that match caps to their corresponding systems. Cross-referencing model numbers with manufacturer documentation prevents compatibility issues that could compromise patient safety. Healthcare facilities should maintain reference charts linking equipment serial numbers to appropriate replacement parts.

Physical characteristics offer additional identification clues when markings become illegible. Cap diameter, thread patterns, and color coding help distinguish between different models. However, visual identification should always be confirmed through documentation review before proceeding with replacement.

Consulting with medical equipment specialists provides expert guidance for complex identification scenarios. These professionals maintain comprehensive databases of compatible parts and can resolve uncertainty about appropriate replacements. Their expertise proves invaluable when dealing with older equipment or discontinued models.

Safe Removal of Old Caps

Proper removal techniques prevent contamination while protecting both equipment and personnel. Begin by gathering necessary supplies including sterile gloves, antiseptic solution, and appropriate disposal containers. Creating a clean workspace reduces infection risks and ensures sterile conditions throughout the process.

Hand hygiene represents the first critical step in safe cap removal. Thorough handwashing followed by sterile glove application creates the foundation for aseptic technique. Healthcare providers should follow institutional protocols for hand hygiene and personal protective equipment use.

Gentle counter-clockwise rotation typically releases threaded caps without excessive force. Applying steady, even pressure prevents sudden disconnection that could cause spillage or contamination. If resistance occurs, inspect for debris or damage that might impede removal before applying additional force.

Document the condition of removed caps to identify patterns that might indicate systemic issues. Photography can provide valuable reference material for training purposes and equipment evaluation. Proper documentation supports quality improvement initiatives and helps optimize replacement schedules.

Step-by-Step Installation of New Bard Dispoz-a-Bag Caps

Successful installation requires careful attention to sterile technique and proper alignment. Begin by inspecting the new cap for defects or damage that might compromise performance. Manufacturing defects, though rare, can occur and should be identified before installation to prevent system failure.

Clean the connection point with appropriate antiseptic solution, removing any residue or debris that might interfere with proper sealing. Allow adequate drying time to ensure antiseptic effectiveness while preventing contamination from cleaning materials. The connection surface must be completely clean for optimal seal formation.

Align the new cap with connection threads, ensuring proper orientation before beginning installation. Cross-threading represents a common installation error that can damage both the cap and the connection point. Gentle initial rotation helps identify proper thread engagement before applying full installation pressure.

Hand-tighten the cap using steady clockwise rotation until resistance indicates full engagement. Avoid over-tightening, which can damage sealing surfaces or create stress concentrations that lead to premature failure. The cap should feel secure without requiring excessive force to achieve proper positioning.

Perform a visual inspection to confirm proper seating and alignment. The cap should sit flush against the connection surface with no visible gaps or misalignment. Any irregularities suggest installation problems that require immediate correction to prevent system failure.

Maintenance Tips for Extended Cap Lifespan

Regular inspection schedules help identify developing issues before they require emergency replacement. Visual examinations should focus on seal integrity, thread condition, and overall structural soundness. Early detection allows planned replacement during convenient timeframes rather than emergency situations.

Proper cleaning techniques preserve cap materials while maintaining sterility standards. Use manufacturer-approved cleaning solutions that effectively sanitize without causing material degradation. Harsh chemicals or abrasive cleaning methods can accelerate wear and reduce cap lifespan significantly.

Storage conditions significantly impact cap longevity and performance. Maintain consistent temperature and humidity levels while protecting caps from direct sunlight or extreme environmental conditions. Proper storage prevents premature aging and ensures caps perform as designed when installed.

Handle caps with care during routine procedures to minimize mechanical stress. Gentle operation extends service life while maintaining system integrity. Training staff in proper handling techniques reduces damage rates and improves overall system reliability.

Sourcing Genuine Bard Dispoz-a-Bag Replacement Caps

Authentic replacement parts ensure compatibility and maintain safety standards established by original equipment specifications. Genuine Bard components undergo rigorous quality testing that guarantees performance under clinical conditions. Third-party alternatives may not meet these exacting standards, potentially compromising patient safety.

Authorized medical supply distributors provide reliable sources for genuine replacement caps. These suppliers maintain proper storage conditions and inventory rotation that ensures fresh, high-quality components. Established relationships with authorized distributors support consistent availability and competitive pricing.

Direct ordering from Bard representatives offers access to technical support and product expertise. Factory-trained specialists can answer questions about compatibility, installation procedures, and troubleshooting techniques. This direct relationship provides valuable resources for complex situations or unusual requirements.

Bulk purchasing arrangements often provide cost savings while ensuring adequate inventory levels. Healthcare facilities with predictable replacement schedules can negotiate favorable terms that reduce per-unit costs. Proper inventory management prevents emergency situations that might require premium pricing for expedited delivery.

Ensuring Optimal Patient Care Through Proper Maintenance

Consistent Bard Dispoz-a-Bag cap replacement practices contribute significantly to positive patient outcomes and system reliability. Healthcare providers who master these techniques provide better care while reducing the risk of complications that could compromise patient safety. Regular maintenance schedules prevent unexpected failures that disrupt care delivery.

Professional development in equipment maintenance enhances clinical skills and improves job performance. Understanding proper replacement techniques builds confidence in handling medical equipment while developing problem-solving abilities that benefit patient care. These skills represent valuable professional assets in healthcare careers.

Quality assurance programs that include regular cap inspection and replacement demonstrate commitment to excellence in patient care. Documented maintenance procedures support accreditation requirements while providing evidence of systematic approaches to equipment management. These programs enhance facility reputation and support positive patient satisfaction scores.

Leave a Reply